test-blog

Follow safety precautions around PTOs & hydraulics to prevent farm accidents

Posted on September 4, 2021 8:00 PM

Article & Photos by Jay Stone

The Penn State University Cooperative Extension fact sheet for PTO safety includes examples of incidents where farmers got tangled in the PTO or a drive shaft connected to it.

The descriptions almost read as if Stephen King wrote them: an arm torn off at the shoulder socket; muscle damage to lower leg; multiple injuries to multiple body parts; death.

The PTO is the nub of metal protruding from the tractor’s rear axle. When the tractor engine is engaged, it spins at 540 revolutions per minute (rpm) or 1,000 rpm. Implements are connected by a drive shaft. If either the PTO or the drive shaft is exposed and catches a farmer’s clothing, the cloth is quickly spooled to the equipment, dragging the farmer with it.

On modern tractors, both PTO and implement drive shafts come with safety guards. The PTO is shielded by a frame of metal attached to the axle. The drive shafts often are encased in a loose plastic sheath that stays stationary as the drive shaft spins.

UGA Professor Glen Rains, whose work includes research on safety topics, maintains that even with those safety features, it’s best to maintain awareness of how close you are to the PTO and make it a habit to avoid being near it.

“One thing we always tell people is don’t work around a PTO,” Rains said. “Just a slip and you can fall into it. Never work around it. Don’t step over it. Make it a habit to not even work around it, even if it’s not on.”

Rains offered other tips to keep PTO work to its intended purpose:

• Always keep the shields on the PTO. If the shield is spinning, it’s not providing proper safety.

• Keep people, especially children, away from the PTO.

• Turn the tractor off to disengage the PTO before you get off the tractor to work on your equipment.

“Basically, if you create good habits to not do those things, even if you’re in

a hurry or tired, you won’t make a mistake and get inadvertently caught up in the PTO,” Rains said. “You don’t want to have to think about it because of the possibility that you’re in a hurry or you’re thinking about taking shortcuts. It just takes one bad shortcut to end badly.”

For more on PTO safety, visit www.gfb.ag/PTOsafety.

PTO SAFE SETUP – The three-sided frame above the PTO & the black plastic cylinder around the drive shaft make this a safer connection.

PTO UNSAFE SETUP – The exposed metal of both the PTO shaft and the drive shaft make this connection hazardous.

HYDRAULICS

Similar to PTO, hydraulics enable farmers to perform any task where extraordinary force is required. Rains said that when used with a tractor, a three-inch hydraulic cylinder can move about 13,000 pounds - about the weight of a fully grown male elephant.

Hydraulics pose hazards for pinching/crushing injuries and fluid punctures or burns from leaking fluid.

“I always tell farmers or anyone working with hydraulics to not rely on hydraulics as the sole source of power if you are working underneath equipment,” Rains said. “If you want to raise the front end of a cotton picker and get underneath and work on it, I would put something solid between the ground and the header in case somebody accidentally hits the lever that lets the header down, or there’s a hydraulic failure.”

Hydraulics rely on pressurized fluids, usually oil-based, which become heated under pressure.

Other tips for hydraulics safety:

• Check your hydraulic lines annually for damage. If the plastic covering is cracked or if there is exposed reinforcement or braiding showing, consider replacing those hoses to prevent leaks.

• Check hydraulic fluid levels. Maintain at the right level. Too low can cause cavitation inside the hoses, which can cause little slivers of metal to get loose increasing the chances of failure.

• Keep hydraulic ports marked to ensure the implement hoses are connected to the correct control from the tractor seat.

Rains noted that improperly connected hoses can result in the implement moving down when the up control is engaged, creating a crush hazard if someone is working beneath or within the implement.

“I think the main thing is to check your hydraulic lines every year for damage,” Rains said. “If the plastic covering is cracked or if there is exposed reinforcement or braiding showing, it may be time to look for replacing those hoses, so you don’t have these load failures or burst lines.”

For more on hydraulics safety, visit www.gfb.ag/hydraulic-safety.

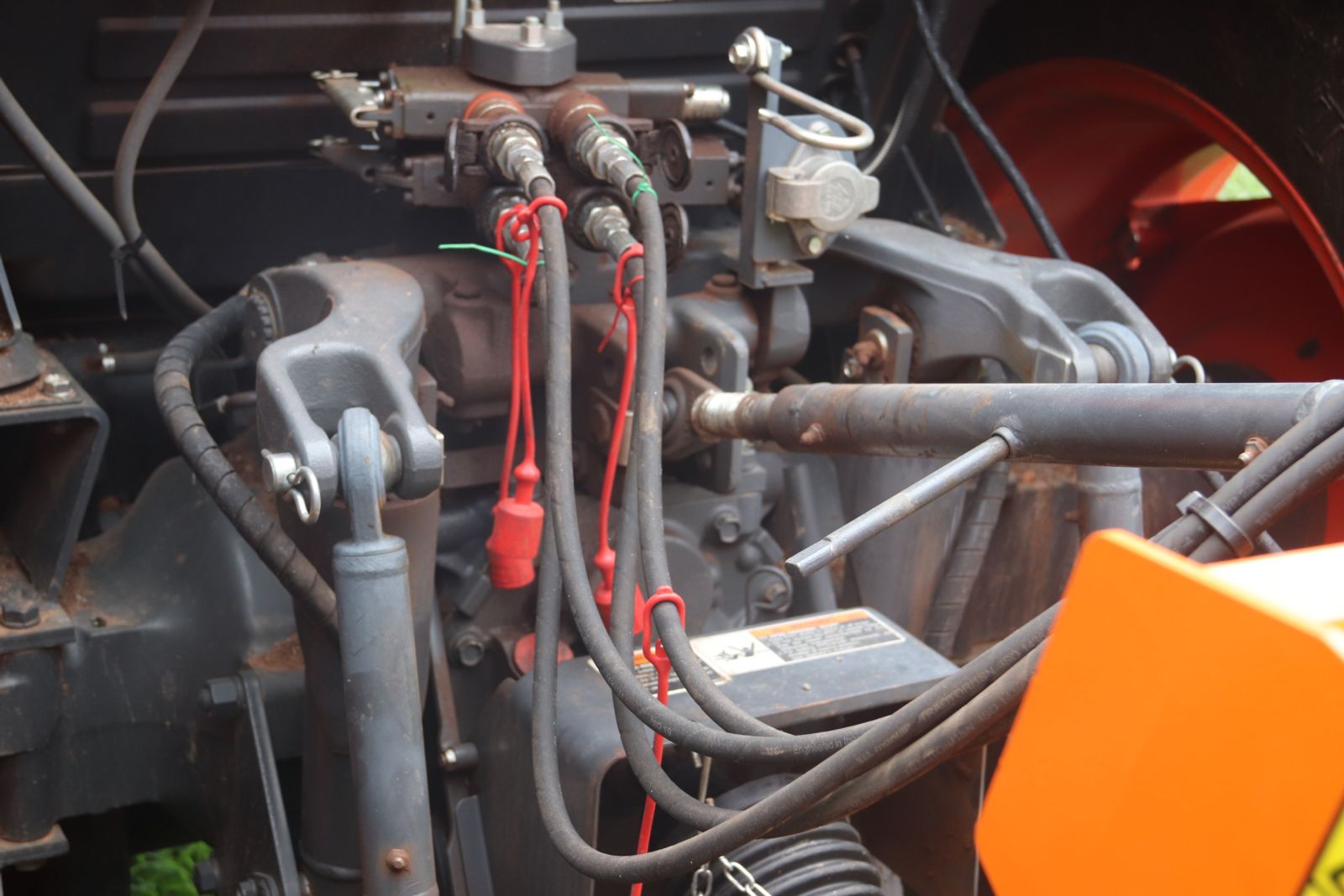

GOOD HOSES – These hoses are in good condition.

TIME TO REPLACE – The cracked covering on these hoses indicate a potential leak hazard.

-GFB-